Descrizione del prodotto:

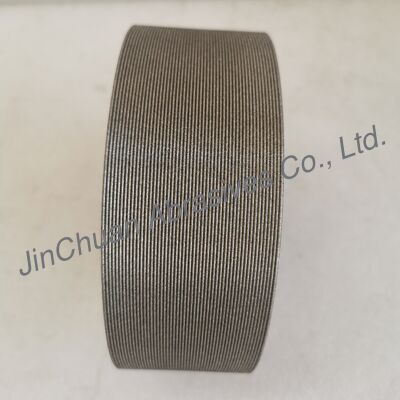

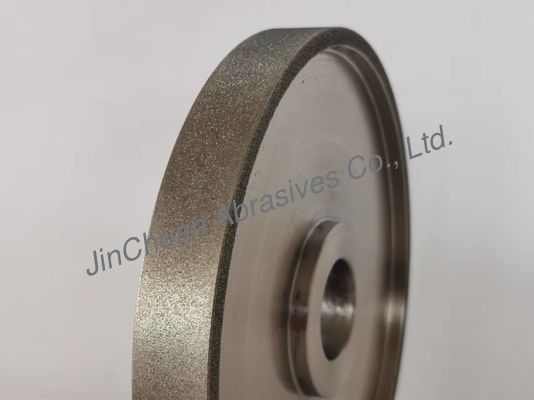

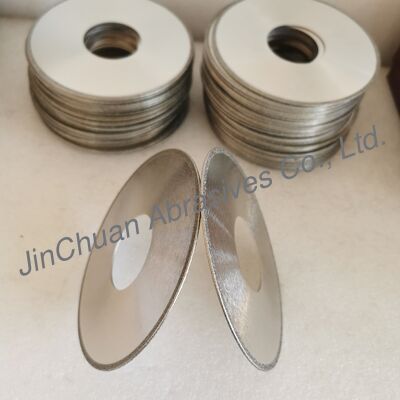

"Rotola ibrida" è un termine tecnico che si riferisce generalmente a una rotella ibrida.

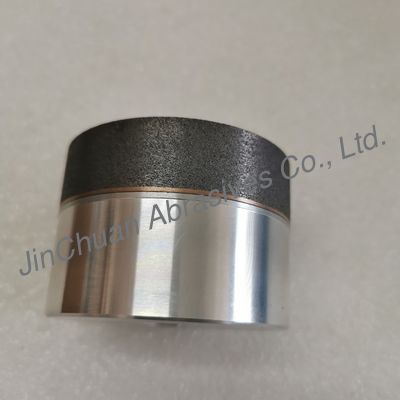

In poche parole, una macina Hbrid è uno strumento abrasivo ad alte prestazioni realizzato combinando due o più tipi diversi di abrasivi (resina, ceramica,e legati al metallo) all'interno di un unico disegno della ruota di macinazione.

Le rulli di rettifica tradizionali utilizzano in genere un solo tipo di abrasivo primario (ad esempio, tutto il corindone o tutto il carburo di silicio).La filosofia di progettazione delle macine ibride è quella di "compensare le debolezze dell'altro"," proporzionare e combinare scientificamente abrasivi con proprietà diverse per ottenere prestazioni superiori che non possono essere ottenute con un singolo abrasivo.

Caratteristiche:

Le macine ibride rappresentano un'importante direzione di sviluppo nella moderna tecnologia abrasiva.ma integrare i vantaggi dei diversi abrasivi attraverso un approccio di "lavoro di squadra", raggiungendo:

- Velocità di taglio più elevate

- Vita di servizio più lunga

- Migliore qualità di lavorazione

- Applicabilità più ampia

Parametri tecnici:

| Abrasivi |

CBN |

| Pacco |

uno in scatola |

| Diametro |

75 mm |

| Spessore |

52 mm |

| Corpo di base |

Aluminici |

| Fuoco interno |

20 mm |

| Larghezza dell'abrasivo |

10 mm |

| Dimensione della grinta |

B126 |

| Paese d'origine |

Cina |

| Imballaggio |

Uno in scatola. |

| Codice HS |

6804221000 |

| - Spiccato. |

Acciaio a vaso |

| Tipo di obbligazione |

Ibriti |

Applicazioni:

Le combinazioni abrasive tipiche delle macine ibride sono:

1. Resina + legame metallico: questa è la combinazione più comunemente utilizzata.

2. Ceramica + Metal Bond: Questa è una combinazione comunemente usata al giorno d'oggi.

3. Resina + Ceramica + Legame metallico: Questa è la combinazione più resistente e più performante.

CBN + ibrito: durante la lavorazione di materiali superduri, il CBN (nitruro di boro cubico) viene miscelato con altri abrasivi ausiliari per ottimizzare le sue prestazioni nella lavorazione di materiali specifici.

FAQ:

D1: Offre campioni?

A1: vogliamo sinceramente cooperare con voi, quindi forniremo campioni da testare.

Q2: Qual è la quantità minima d'ordine e il prezzo unitario?

R2: La maggior parte dei nostri prodotti sono personalizzati, quindi la quantità minima di ordine e il prezzo unitario variano a seconda del prodotto.

Q3: Come spedite i vostri prodotti?

A3: spediamo tramite espresso internazionale come FedEx, UPS, TNT, EMS, DHL, SF Express, ecc. Per ordini di grandi dimensioni, possiamo scegliere di spedire via mare.Puoi scegliere di ritirare la merce dal porto più vicino a te.

Q4: Quali materiali vengono utilizzati nei vostri prodotti?

R4: I nostri abrasivi utilizzano principalmente diamanti e CBN. Possiamo raccomandare un legame adatto in base alle vostre esigenze, tra cui legami elettroplata, resina, ceramica e metallo.

Q5: Puoi fornire diversi tipi di imballaggi in base alle esigenze del cliente?

A5: Sì, possiamo etichettare e confezionare in base alle vostre esigenze.

Q6: Come puoi garantire la qualità?

A6: abbiamo un completo sistema di gestione della qualità, gestire rigorosamente la qualità durante il processo di produzione e fornire un servizio post-vendita uno a uno.

Q7: Quanto tempo si prevede per la consegna?

A7: Dopo aver effettuato l'ordine, pagato e confermato i disegni, organizzeremo la produzione. La consegna dovrebbe richiedere circa 7-10 giorni.

D8: Posso spedire tramite il mio agente di spedizione?

A8: Sì, se avete il vostro spedizioniere, potete venire a ritirare la merce.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!