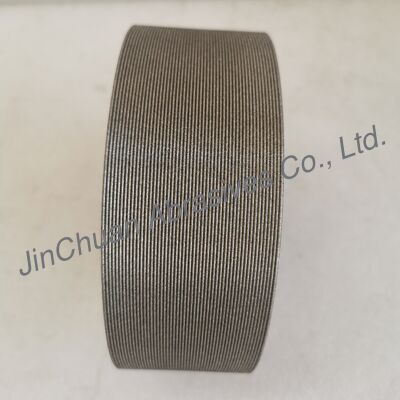

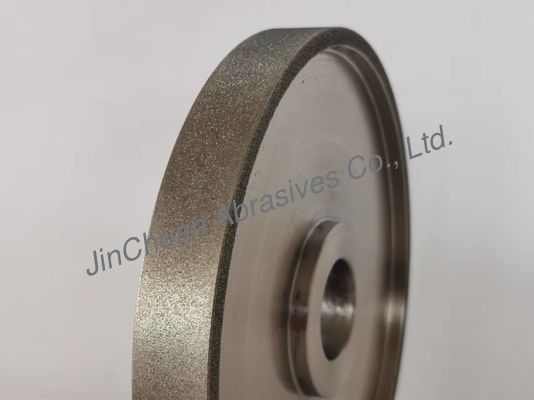

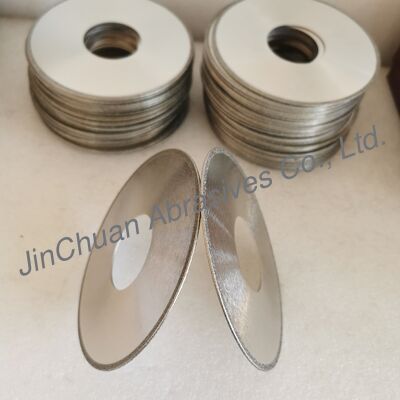

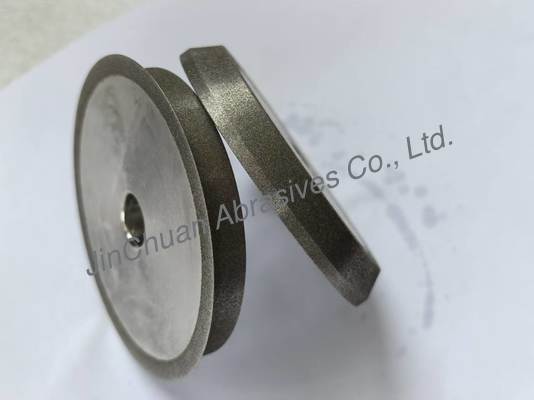

Diamond And Cbn Electroplated Chamfering Wheels For Grinding Endmills

Product Information Of Electroplated CBN wheel for chamfering

Electroplated CBN chamfer wheels are specialized, high-performance tools designed for creating precise, clean, and durable beveled edges (chamfers) on exceptionally hard materials. They leverage the unique properties of the electroplated CBN bond for superior results in demanding applications.

Main Applications:**

* **Chamfering Hardened Steels:** Bearings, gears, shafts, automotive components (cranks, camshafts, transmission parts), hydraulic components, cutting tool blanks.

* **Chamfering Tool Steels & High-Speed Steel (HSS):** Drills, end mills, taps, reamers, inserts, saw blades.

* **Chamfering Cemented Carbides (Tungsten Carbide):** Inserts, dies, wear parts.

* **Chamfering Superalloys:** Inconel, Waspaloy, Hastelloy (common in aerospace & power gen).

* **Deburring & Edge Radiusing:** While primarily for defined chamfers, they can also be used for precise deburring and creating small, consistent corner radii on hard materials.

Main Data Of Electroplated cbn chamfering wheels

| Technical Parameter |

Details |

| Size |

125*10*32*20mm 78*10*12.7*5mm |

| Hs Code |

6804211000 |

| Base Body |

Steel |

| Shape |

1EE1 |

| Material |

CBN, Steel Basebody |

| Packing |

Standard Exported Carton Packing |

| Package |

Color Box |

| Country Of Origin |

China |

| Application |

Grinding and Sharpening

|

Advantages:

1. **Exceptional Edge Quality & Consistency:** Produces clean, sharp, and burr-minimized chamfers with excellent surface finish due to the sharp CBN grains and free-cutting action.

2. **Long Wheel Life & Form Retention:** CBN's extreme hardness and wear resistance, combined with the rigid electroplated bond, mean the wheel holds its precise chamfer angle profile far longer than conventional abrasive wheels. This is crucial for consistent chamfer geometry over thousands of parts.

3. **No Dressing Required:** Comes ready-to-use and maintains its form throughout its life. Eliminates downtime and complexity associated with dressing conventional or vitrified bonded wheels.

4. **High Cutting Efficiency:** The exposed grains and CBN's hardness allow for efficient material removal with relatively low cutting forces and heat generation, reducing the risk of workpiece burn (especially critical on hardened materials).

5. **High Speed Capability:** Designed to run at high peripheral speeds (often 80-160 m/s), increasing throughput.

6. **Suitable for Very Hard Materials:** Excels where conventional abrasives (AlOx, SiC) wear out too quickly or diamond is unsuitable (ferrous materials).

7. **Versatility in Design:** Can be made in various diameters, widths, and specific angles to suit different machine setups and part geometries.

Electroplated CBN chamfer wheels are the premium solution for high-precision, high-volume chamfering of hard materials. Their outstanding form retention, long life, no-dress operation, and ability to produce superior edge quality make them indispensable in demanding manufacturing environments like aerospace, automotive, cutting tool production, and precision bearing manufacturing. Success hinges on using them on suitable materials with a rigid machine setup, abundant coolant, and correct operating parameters.

NOTE: If you do not find the product you want in this website, contact us first, we can design and produce any specification of grinding wheels as customer's requirement.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!