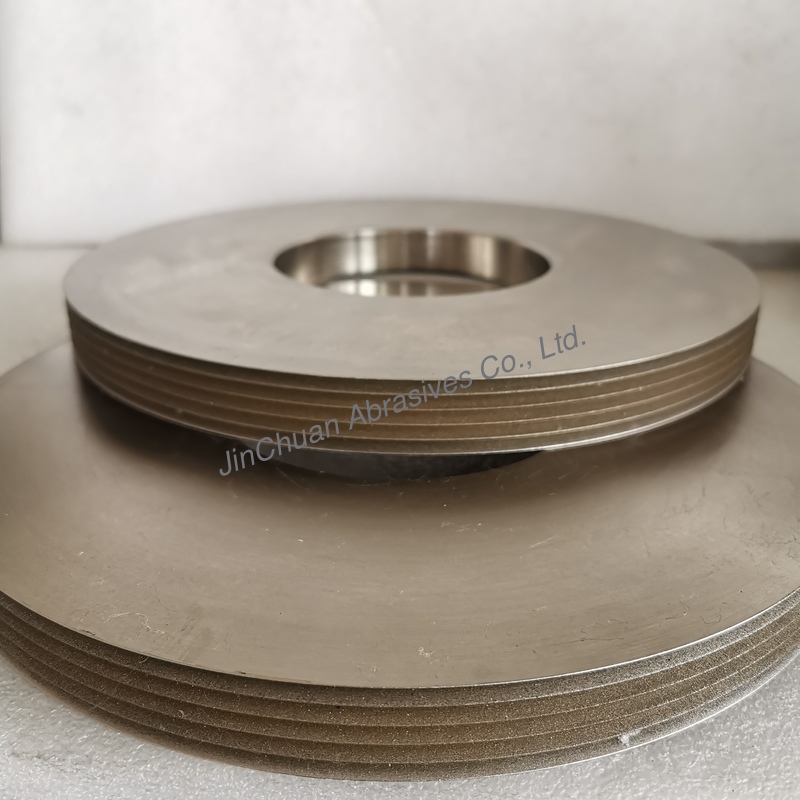

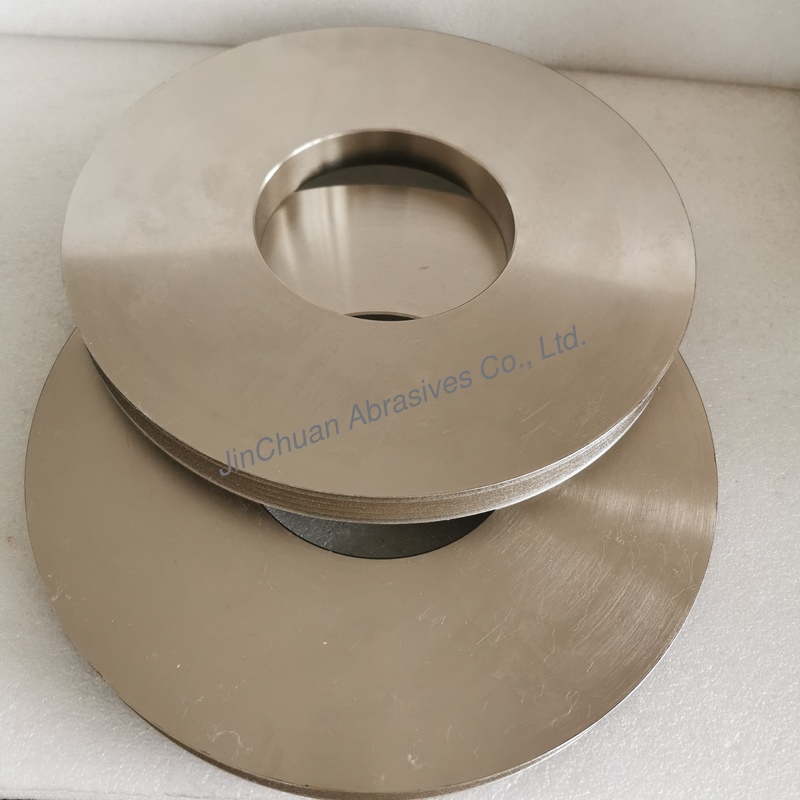

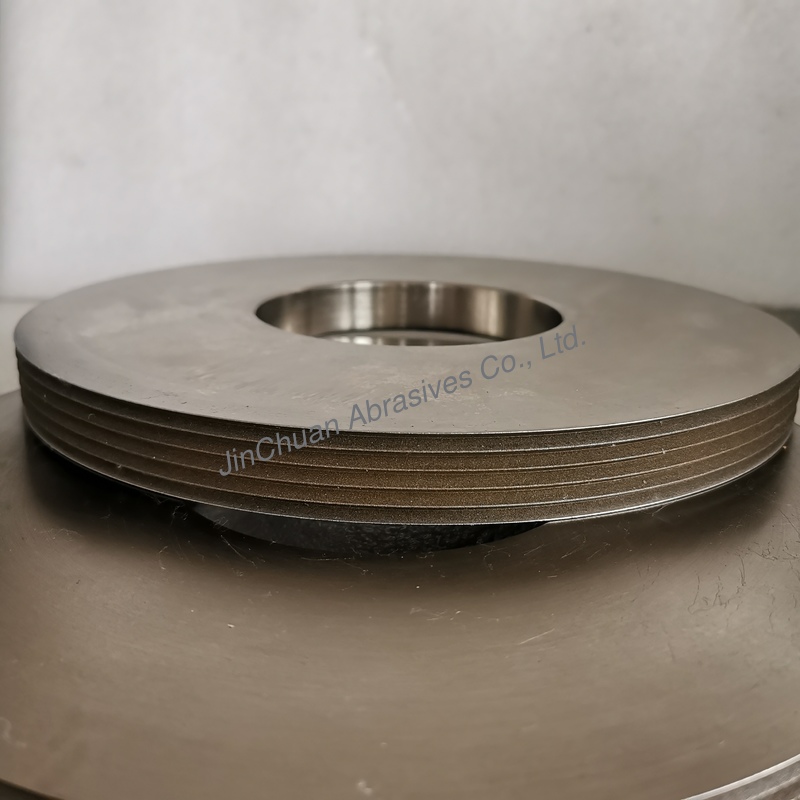

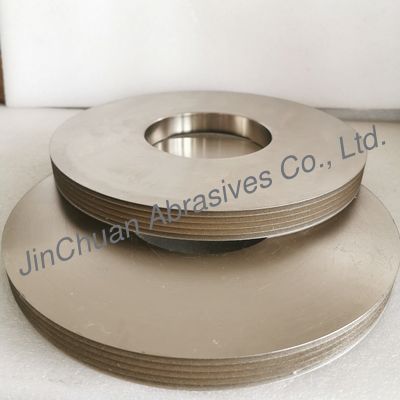

Electroplated CBN Cup-Shaped Grinding Wheel 1E1SP 300*127mm B200/203 with Grooved

-

Evidenziare

Electroplated CBN grinding wheel 300mm

,CBN cup-shaped wheel B200/203

,Grooved grinding wheel 1E1SP

-

Diametro300 mm

-

Spessore25,4 mm

-

Corpo di baseAcciaio

-

Dimensione della grintaB200/230

-

Paese di origineCina

-

Pacchettouno in scatola di carta

-

AbrasivoCbn

-

FormaRotondo con scanalato

-

Tipo di obbligazioneElettroplato

-

DurezzaCome richiesto

-

Buco interno127 mm

-

EquilibrioEquilibrio dinamico

-

Codice Hs6804221000

-

Colore del cartoneViola

-

Luogo di origineHenan, Zhengzhou

-

MarcaJC

-

CertificazioneISO

-

Numero di modello1E1SP

-

Quantità di ordine minimo2

-

PrezzoNegoziabile

-

Imballaggi particolariuno in scatola di carta

-

Tempi di consegna7 giorni

-

Termini di pagamentoTT, Western Union, Paypal, L/C

-

Capacità di alimentazione10000/mese

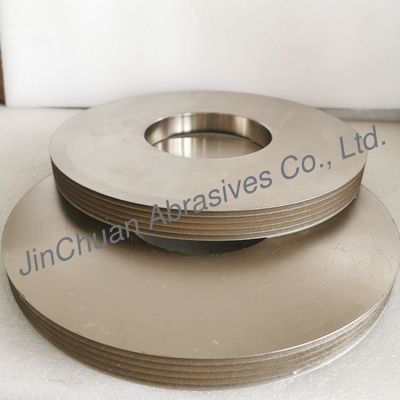

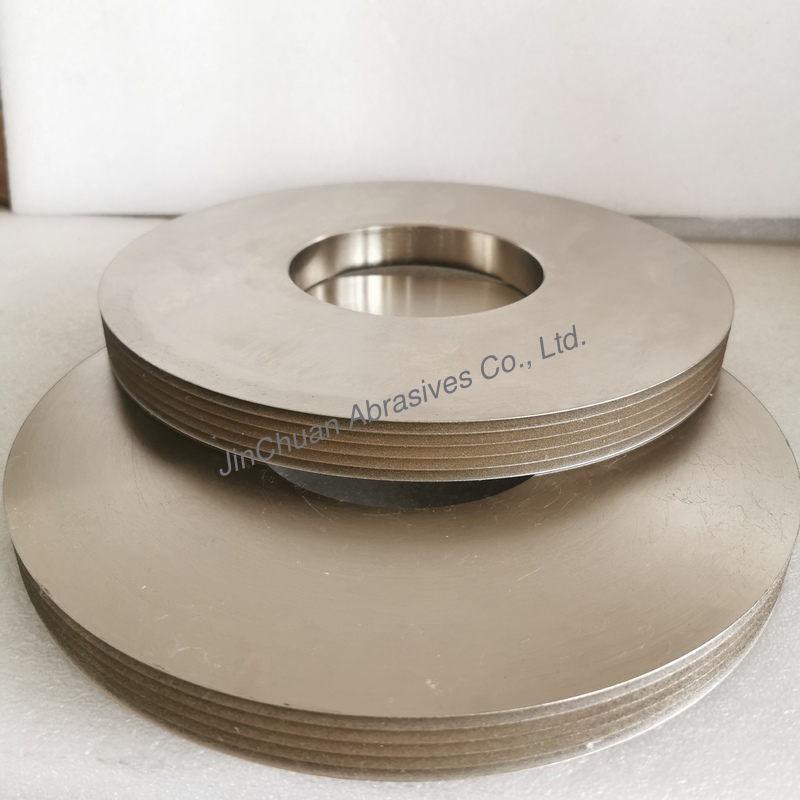

Electroplated CBN Cup-Shaped Grinding Wheel 1E1SP 300*127mm B200/203 with Grooved

Product Description:

Superabrasive is a term used to describe Diamond and CBN (Cubic Boron Nitride). Diamond is the hardest substance on the Knoop Hardness Scale and the only abrasive capable of grinding ultra-hard materials. CBN is a new type of artificially synthesized material developed in the 1950s, with a hardness second only to diamond . They can both applied. Althougth CBN and Diamond are both superabrasive, the areas of use vary consid-erably by material. In general, diamond is used for grinding non-metallic hard and brittle materials, while CBN is used to grind ferrous materials.

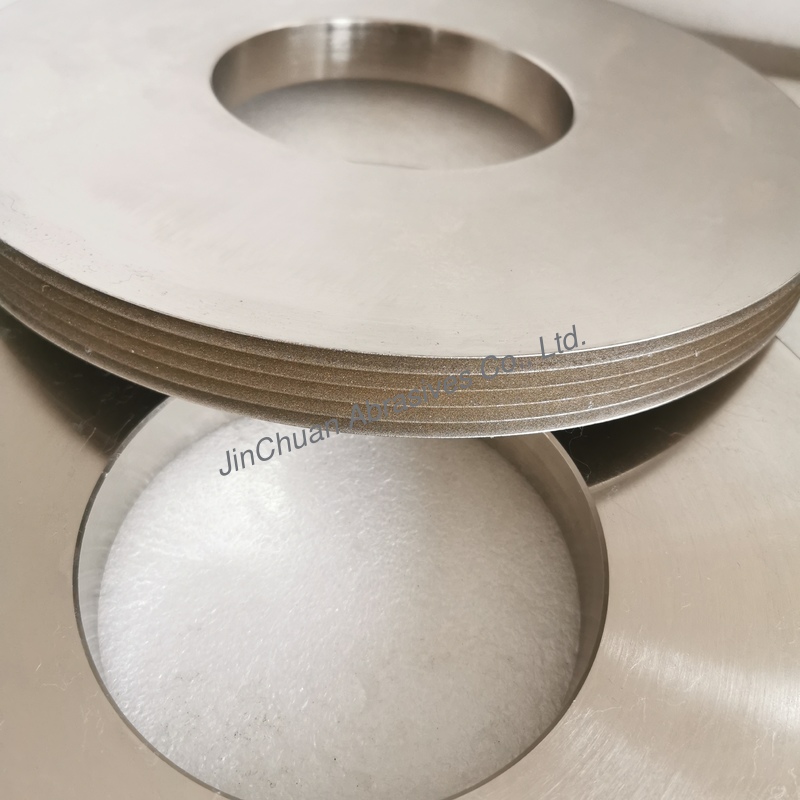

Electroplated CBN grinding wheels are grinding tools made by firmly encapsulating CBN particles onto a metal substrate (steel or aluminum) through an electroplating process (typically using nickel or a nickel-cobalt alloy). CBN grinding wheels are renowned for their unparalleled sharpness, excellent shape retention, and extremely high grinding efficiency, making them ideal for precision forming and high-speed grinding of hard and tough materials.

CBN grinding wheels can be mainly classified into metal-bonded, ceramic-bonded, resin-bonded, and Hybrit mixed-bonded types according to the type of bond. With a hardness second only to diamond, it is an ideal material for manufacturing superhard abrasives and cutting tools.

Features:

- Product Name: CBN Grinding Wheels

- Base Body: Steel

- Country Of Origin: China

- Grit Size: 200/230

- Application: Stellite Teeth

- High temperature resistance

- Not easy to carbonize

- High machining precision

Technical Parameters:

| Abrasives | CBN |

| Package | one in box |

| Diameter | 300mm |

| Thickness | 25.4mm |

| Base Body | Steel |

| Inner hole | 127mm |

| Sharp | Round with Grooved |

| Grit Size | B 200/230 |

| Country Of Origin | China |

| Hs Code | 6804221000 |

| Bond type | Electroplated |

| Balance | Dynamic balance |

Applications:

Cutting tools: Primarily used for high-speed cutting of difficult-to-machine materials such as hardened steel, cast iron, and high-temperature alloys, enabling turning to replace grinding.

Abrasives: Used to manufacture grinding wheels for machining high-hardness ferrous metal parts and electronic components.

Others: Also used as polishing paste and in the manufacture of heat sinks.

It can maintain its hardness at high temperatures and its heat resistance is far superior to that of diamond, allowing for high-speed cutting at high temperatures.

FAQ:

Q1: Do you offer samples ?

A1: We sincerely want to cooperate with you, so we will provide samples for you to test.

Q2: What is the minimum order quantity and unit price?

A2: Most of our products are custom-made, so the minimum order quantity and unit price vary depending on the product.

Q3: How do you ship your products?

A3: We ship via international express such as FedEx, UPS, TNT, EMS, DHL, SF Express, etc. For large orders, we can choose to ship by sea. You can choose to pick up the goods at the port closest to you.

Q4: What materials are used in your products?

A4: Our abrasives primarily use diamond and CBN. We can recommend a suitable bond based on your needs, including electroplating, resin, ceramic, and metal bonds.

Q5: Can you provide different types of packaging according to customer needs?

A5: Yes, we can label and package according to your requirements.

Q6: How can you guarantee the quality ?

A6: We have a complete quality management system, strictly manage quality during the production process, and provide one-to-one after-sales service.

Q7: How long do you expect to deliver?

A7: After you place your order, pay, and confirm your drawings, we'll arrange production. Delivery is expected to take approximately 7-10 days.

Q8: Can I ship through my own freight forwarder? Are customers allowed to use their own freight forwarder for shipping?

A8: Yes, If you have your own freight forwarder, you can come to pick up the goods. Or we can ship to your freight forwarder.